HISTORY OF REES

Rare earth elements (REE) are a good example of how society’s need for minerals and metals evolves as new uses for them are invented.

Before 1965 there was relatively little demand for rare earth elements. However, demand for them exploded in the mid-1960s, as the first color television sets were entering the market. Europium was the essential material for producing the color images.

China began producing notable amounts of rare earth oxides in the early 1980s and became the world's leading producer in the early 1990s. Through the 1990s and early 2000s, China steadily strengthened its hold on the world's rare earth oxide market. China was selling rare earths at such low prices that other REE mines throughout the world were unable to compete and stopped operation.

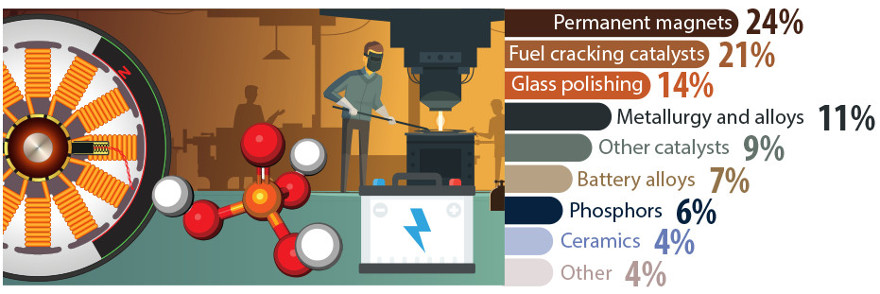

At the same time, world demand was skyrocketing as rare earth metals were designed into a wide variety of defense, aviation, industrial, and consumer electronics products. China capitalized on its dominant position and began restricting exports and allowing rare earth oxide prices to rise to historic levels.

In addition to being the world's largest producer of rare earth materials, China is also the dominant consumer. The Chinese use rare earths mainly in manufacturing electronics products for domestic and export markets. Japan and the United States are the second and third largest consumers of rare earth materials.

The Chinese dominance may have peaked in 2010 when they controlled about 95% of the world's rare earth production, and prices for many rare earth oxides had risen over 500% in just a few years. That was an awakening for rare earth consumers and miners throughout the world. Mining companies in the United States, Australia, Canada, and other countries began to re-evaluate old rare earth prospects and explore for new ones, including in Nova Scotia.

High prices also caused manufacturers to do three things: 1) seek ways to reduce the amount of rare earth elements needed to produce each of their products; 2) seek alternative materials to use in place of rare earth elements; and, 3) develop alternative products that do not require rare earth elements.

This effort has resulted in a decline in the amounts of rare earth materials used in some types of magnets and a shift from rare earth lighting products to light-emitting diode technology. In the United States, the average consumption of rare earths per unit of manufactured product has decreased, but the demand for more products manufactured with rare earth elements has increased. The result has been higher consumption.

Today, rare earth elements are generally used in very small amounts per product, but they are essential to making electronics so small, fast and powerful.

For more information visit: https://geology.com/articles/rare-earth-elements/

RARE EARTH ELEMENTS AND THE ENVIRONMENT

Electric cars need lithium for their batteries.

New “green” products and technological advancements are only possible because of the materials we take from the ground, including rare earth elements. For example, renewable energy technologies such as wind turbines and solar panels require rare earth elements, in addition to many other materials provided by mining.

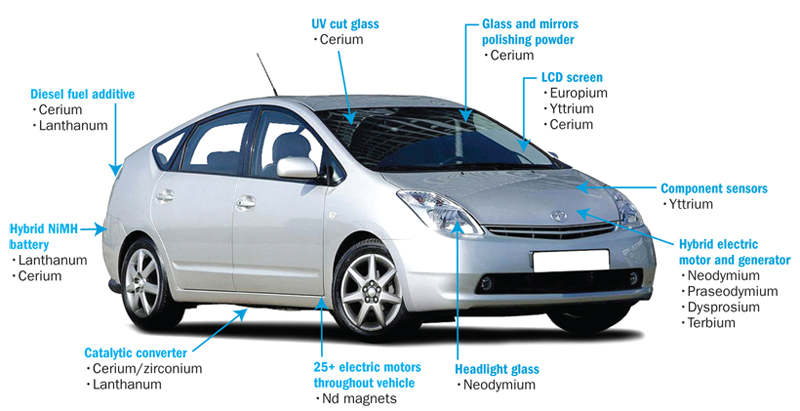

Hybrid vehicles use REE in various ways, including in their batteries, motors, the bodies of the vehicles and their onboard computers.

REE are also in fuel cells and high efficiency light bulbs, and are used in pollution abatement, water treatment and decolorizing recycled glass.

Computers that operate all manner of environmentally-friendly technologies also need REE in order to work.